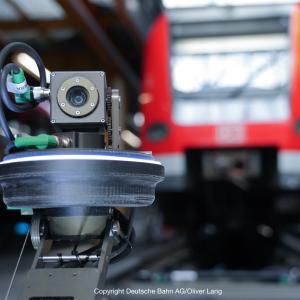

Visual inspection of rolling stocks is commonly performed inside elevated or standard pits. The inspection procedure is performed by qualified operators that report the train status on maintenance forms.

The innovative ARGO platform allows the operator to perform visual inspection from a remote position increasing the safety of the inspection procedures. Moreover, ARGO doesn’t need the pit to work. Such a feature allows to perform visual inspection on every platform, even in train stations reducing the train downtime. ARGO can record and store inspection images of all the trains in a maintenance database allowing operators to monitor the evolution of the train undercarriage status relaying on HQ images and videos. Data collection is the first step to drive visual inspection procedures towards a reliable predictive maintenance approach and AI algorithms for automatic faults detection.

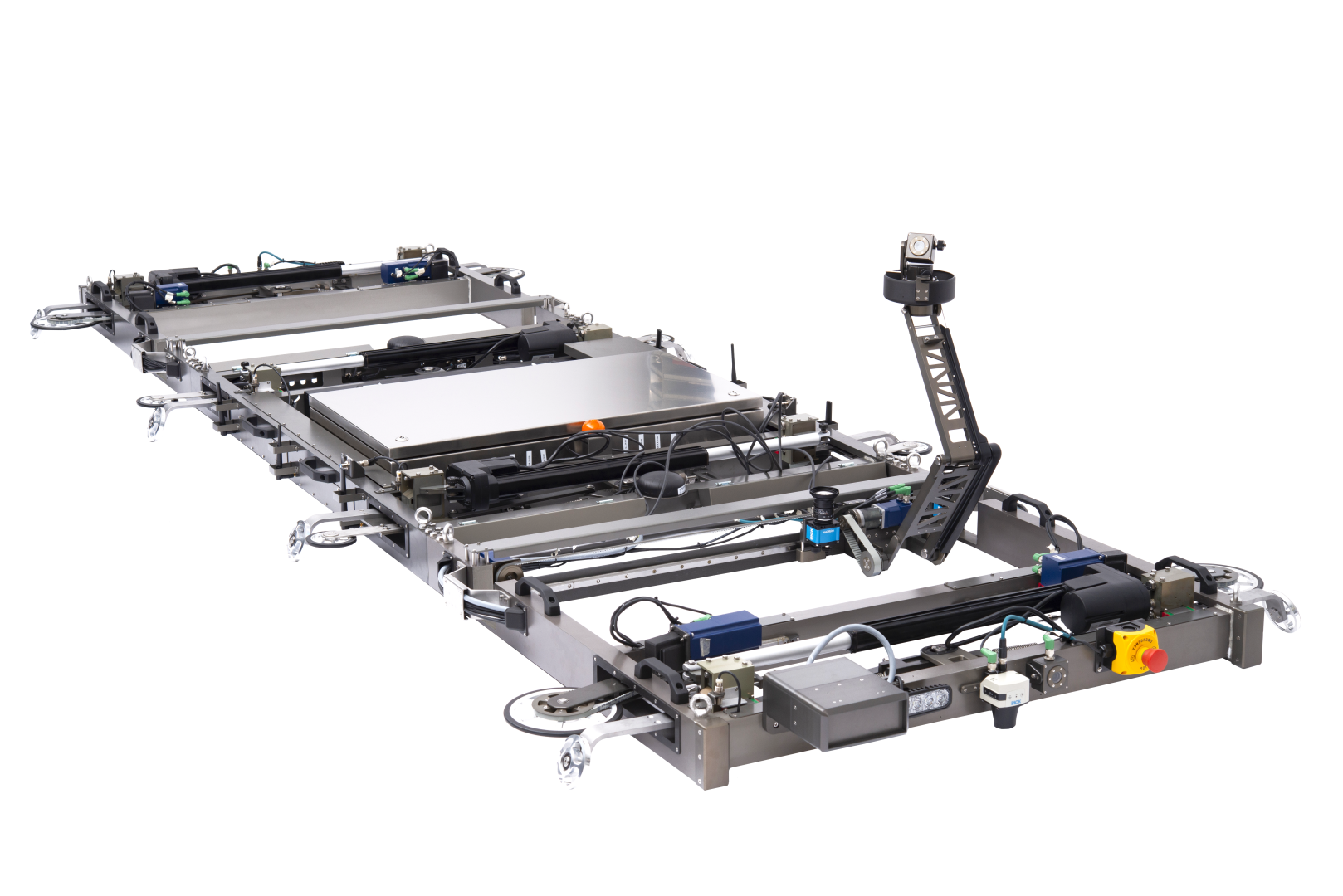

Components

Datasheet

Total Weight

(3 modules)

220 kg

Dimensions

3918 x 1244 x 184 mm

Max Motion Speed

3 m/s

Motion Safety

2x Collision avoidance LiDars

3x Ultrasound sensors 1x Optical sensor

Inspection sensors

2x Horizontal perspective cameras (12 MP)

1x robotic arm camera (5 MP)

Inspection Arm

730 mm extension

Autonomy

10 hours

Charge Time

3 hours Inside track docking station available

Environment

Compatible with the majority of the rail standards

Protection

IP 65

Remote Control

Web Application

FREQUENTLY ASKED QUESTIONS

ARGO can perform remote train undercarriage inspection by safely moving under a train without any risk of collision. It can be remotely operated by a person that can launch automatic scanning procedures or manually teleoperate the robot to take pictures or videos.

ARGO can move thanks to a patented motion system based on wheels rolling on the inner side of the rail. Thanks to its advanced motion system, ARGO can run on any profile and overcome obstacles on the rail.

ARGO can be used on standard rail profile, both on tracks with ballast and on inspection pits.

ARGO creates inspection pits where there is none. It can help you improving the traceability and repeatability of maintenance and inspection procedures, enabling predictive maintenance algorithms.

ARGO gathers precious reliable and repeatable data on trains thanks to its sensors. These data are collected into digitized inspection records that can be used to develop specific AI based predictive maintenance algorithms.

ARGO is a versatile and modular platform that can integrate any sensor you need for undercarriage inspection. Base ARGO modules are designed for visual inspection, furthermore, the modularity design allows to easily customize the product on your sensor requirements.